Novozymes is a biotech-based company, headquartered in Denmark and employing approximately 6,000 people in 30 countries. Its products – industrial enzymes, microorganisms, biopolymers and other proteins – allow industry to achieve more efficient use of raw materials, reduce energy consumption, replace traditional chemicals with more sustainable alternatives, and offer higher-quality products to customers.

Innovation and sustainability are core to Novozymes’ business values and objectives. In committing to innovation, Novozymes hosted some of the world’s leading companies at an Innovation Roundtable on April 9th 2014.

The Roundtable’s focus was on harnessing innovation and targeting initiatives to ensure they have an impact.

“One very effective way to do this is a process known as foresighting. This involves identifying and assessing emerging technologies, needs and problems, and tailoring initiatives to meet these needs. Participants at the roundtable were introduced to some ‘out of the box’ methods to support the foresighting process.” Novozymes’ website.

The business is also very open in its relations with others in its field with partnering seen as a key competency in the drive towards sustainability and to “effectively create and build businesses that can help change the world.”

“At Novozymes we understand the invaluable connections that take place when the right minds find each other. We see innovation-driven partnerships as a key element of delivering tomorrow’s biosolutions, and are looking for companies and technologies to help us develop and market the next generation of ideas.” Novozymes’ website.

Novozymes also acknowledges the importance of driving innovation from the bottom up and understands that engaging with the shop floor is good for employees and good for productivity.

Rosemary Exton and Professor Peter Totterdill met with Line Sandberg, Vice President, Novozymes and Anders Hentze Knudsen, the United Federation of Danish Workers Shop Steward at Novozymes to discuss working practices at the company’s Bagsvaerd operation in Denmark.

The discussion highlighted the ways in which strong partnership between management and unions can transcend traditional industrial relations agendas, empowering frontline workers in day-to-day decision-making and actively involving them in improvement and innovation.

“What’s essential or what’s unique about Novozymes is that we have a very, very strongly embedded improvement culture.”

“What’s essential or what’s unique about Novozymes is that we have a very, very strongly embedded improvement culture.”

Line Sandberg

“It’s very important that we involve the employees and the unions. Novozymes has a very long tradition for involving each other in almost everything, that makes things come easier to the employees.”

Anders Hentze Knudsen

Key points included:

- Engagement – if employees think they’re part of decisions and part of the project, it’s much easier to get it going.

- Communications – weekly meetings to inform and listen. Employees know their views, concerns and issues will be channeled upwards.

- Feedback – suggestion are acted upon. For example administrative tasks were reallocated from shop floor operators to allow them more time to do their core jobs. Shift pattern changes were suggested to make them less stressful but without affecting productivity.

“If they have good ideas and if it can be done, we do it.” Line Sandberg

- Acknowledgment – all suggestions are personalised with the individual making the suggestion given feedback (whether their suggestions are implemented or not) and rewarded.

- Representation – operator and craftsmen representatives are invited to all discussions on new projects, including those with large capital investment, to minimise the threat of later snags in design. Engineers see early input from operators as helpful.

- Training – operators are trained on new equipment before the equipment has been fully designed to fast-track implementation, anticipate possible future problems and to be capable of dealing with operational difficulties after going live.

- “Self-steering teams” – teams determine who should work on a particular task and what range of skills/qualification/experience are required. Self-directing teams are supported by academic staff but often work without a formal leader of manager so are responsible for coordinating the work themselves and identifying any perceived lack of competences required to do the job.

“We want to keep focussed on where the value is created which is out in the factories.”

Line Sandberg

“They (the operators) are dedicated and committed to fulfil their roles even though they may be working without a leader in the room.”

Anders Hentze Knudsen

- Inclusion – operators will often consult with chemists and suggest changes to a process.

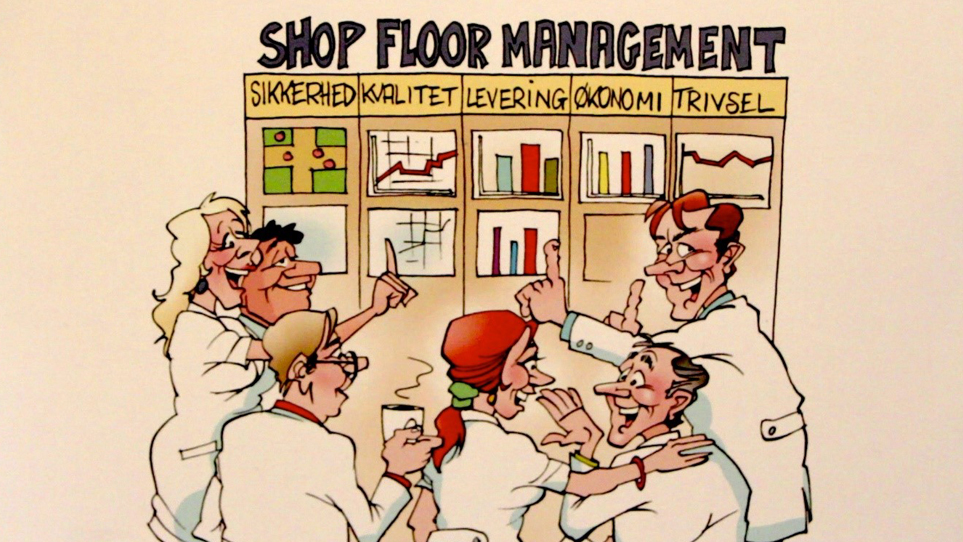

- Making time – scientists, engineers, technicians block their calendars from 8am -10am in order to be available to help the operation running. Stand-up meetings have an agenda of five topics displayed on boards – safety, quality, delivery, financials and satisfaction motivation. The format helps identify issues, allocate resources and deal with targeting and resourcing special assignments.

“It’s very much up to each work centre what they want to put on the board and what they want to talk about. It’s a little bit different from place to place. In some cases they speak about how much do we need to produce today, how many people do we have, what resources do we have today, do we need to reorganise or do we need to change the way that we operate? In other cases they would have a smiley system, one to five how are we doing today, is it a good day or is it a bad day and if it’s a bad day, why is it a bad day, what’s going on? So it’s also a way of talking about how people are feeling.”

Line Sandberg

For Novozymes, ‘Shop Floor Management’ is a way of creating a forum where there is dialogue between employees who are working in the daily operations, the manager and the technical support. It is about ensuring effective and prompt responses to day to day problems, harvesting observations and ideas wherever they come from and seeing that they are communicated across groups and across shifts. It’s leadership on the shop floor.

The company acknowledges workplace innovation as an important idea but does not conceptualise it because they see it evolving from their everyday activity. Where there is a constraint or a problem to solve and that calls for a change in the way that they operate or a new training requirement, they don’t theorise about it but get on and do it.